CASTING

주조

SHINSUNG HITECH

- Information

- Key Products

- Facilities

SHINSUNG HITECH, as a manufacturer specializing in steel and fiber equipment, has secured leading Korean steel giants such as POSCO as customers and has specialized in manufacturing various steel processing equipment.

Over the past two years, the company has invested in diecasting process eqipment and developed technology to diversify its business into eco-friendly automobile parts, successfully mass producing integrated parts that can reduce costs and improve productivity. As the ecofriendly automobile market grows rapidly, the company's sales performance is also steadily improving.

Information

- Address

- 91, Dalseong 2 cha 2-ro, Guji-myeon, Dalseong-gun, Daegu Met- ropolitan City, Korea

- Fax

- Website

- http://www.sshitech.kr

Products

Electric vehicle traction motor parts, steel shearing equipment

Certifications

Electric vehicle traction motor parts, steel shearing equipment materials and parts specialized businesses, venture businesses, INNOBIZ, ISO 9001

Production Facilities

Diecasting machines (3550 ton, 2500 ton, 1250 ton, 1100 ton, 850 ton, 350 ton), conveyor short machines

Ppuri Technologies

Near-net shape casting technology

History

-

2022 Selected as a prestar company by Daegu Metropolitan City. The company has applied for one patent.2021: Designated as a venture business, INNOBIZ (a technologically innovative small and medium sized business), a company specializing in materials and parts equipment, and Ppuri technology specialized company (a company specializing in source technology). The company has applied for two patents.

2020 Won ISO 9001 certification

2017 Changed company name to Shinsung Hitech Co., Ltd.

2013 Awarded the 3 Million Dollar Export Tower

2011 Established a corporate affiliated R&D Center

2010 Established NSHI

Business Details and Production Items

The company has entered the ecofriendly automobile parts market by converting its business from specializing in steel shearing equipment and textile machinery to manufacturing diecasting parts and diversifying its business. The company is mass-producing excellent products by combining various technologies, from mold design using its long-standing design technology to post-processing including the casting process.

Features

The company has secured modular design and casting technology close to the nearnet shape based on an integrated design that can meet customers' demand for cost reduction through the possession of large diecasting equipment.

- Information

- Key Products

- Facilities

Key Products

-

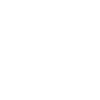

Steel slitting facility

Steel slitting facility

-

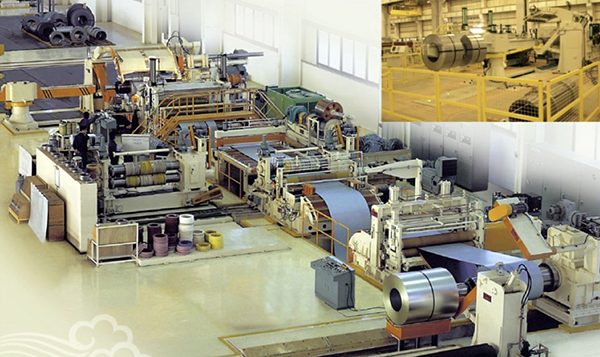

Traction motor housing

Traction motor housing

-

Rotary shearing line

Rotary shearing line

- Information

- Key Products

- Facilities

Production Facilities

-

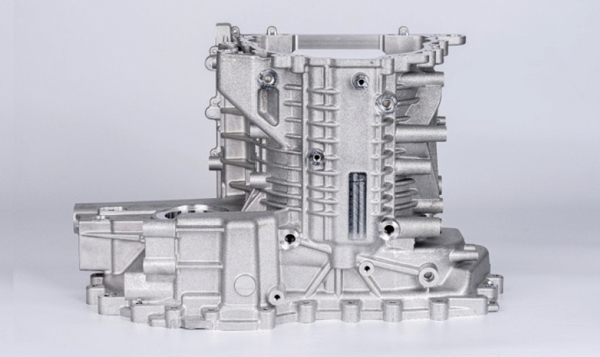

Traction motor automated processing line

Traction motor automated processing line

-

Automatic leak inspection and sub- assembly line

Automatic leak inspection and sub- assembly line

-

3550-ton diecasting machine

3550-ton diecasting machine

-

850-ton diecasting machine

850-ton diecasting machine

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR