CASTING

주조

SHINHWA

- Information

- Key Products

- Facilities

SHINHWA has recognized the vision of future electronic parts and automobile lightweight materials from early 2000, the early days of Korea's magnesium industry. Since then, the company has been striving to improve resource efficiency and secure cost competitiveness of parts makers through recycling and processing of magnesium scrap.

Besides, the company is providing the best solutions to customers by expanding its product range to manufacture master alloys for special purposes, other magnesium gravity castings, and billet manufacturing. The company is accumulating refinement technologies for producing high quality products and always practices quality and environmental management by securing ISO9001, 14001, and TS16949 certifications for stable quality management.

In response to the continuous increase in demand, the company is making efforts to improve the quality of recycled ingots and increase production efficiency by replacing existing manual lines with automated lines and ecofriendly production equipment on an annual basis.

Information

- Address

- 276-40 Anyang-ro, Saengrim-myeon, Gimhae-si, Gyeong- sangnam-do, Republic of Korea

- Tel

- +82 55-335-3701

- Fax

- Website

- http://www.shinhwamg.com

Products

Recycling of magnesium scrap, development of magnesium sand/ gravity casting, manufacturing of special purpose magnesium master alloy, development of magnesium alloy, etc.

Certifications

ISO 9001, ISO 14001, Company-affiliated R&D Center, Certified as a specialized material and parts company, etc.

Production Facilities

1 ton melting furnace, automatic system, pumping device, mold conveyor, etc.

Ppuri Technologies

Technology for continuous casting of functional nonferrous metals (Al, Cu, Ag, Si, Ti, etc.) including

History

-

Mar. 2003 Samho Magnesium Co., Ltd. founded

Jun. 2006 Built a new plant

Sep. 2006 Changed company name to Shinhwa Co., Ltd.

Jan. 2007 Registered as a member company of Korea Magnesium Technology Research Association

Mar. 2007 Acquired ISO/TS 16949 certification

May. 2009 Selected as a production environment technology developer by the Small and Medium Business Administration

Sep. 2010 Certified as a CLEAN business site

Mar. 2017 Established a company-affiliated R&D Center

Sep. 2018 Built an automatic production line

Jun. 2019 Registered as a company specializing in parts and materials

Sep. 2019 Acquired ISO 9001/14001 certification

Business Details and Production Items

Magnesium Ingots: AZ91D, AZ80A, AZ63, AZ61, AM60B, AM50A, AZ31B

In addition to the above materials, the company can manufacture various alloys and master alloys according to customer needs.

Features

· Construction of Enterprise Resource Planning (ERP) for alloy manufacturing line· Securing of alloy powder and feedstock device technology for 3D printing

· Analysis of 3D printing-applied product structure and preparation of design plan

- Information

- Key Products

- Facilities

Key Products

-

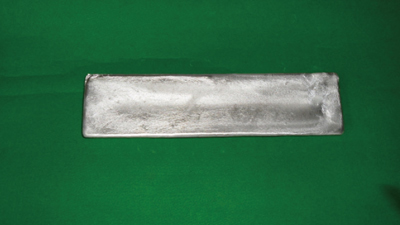

AZ91D ingot

AZ91D ingot

-

AZ91D ingot

AZ91D ingot

-

AM60B ingot

AM60B ingot

-

AM60B Ingot

AM60B Ingot

-

Ingot

Ingot

-

Ingot

Ingot

-

Ingot

Ingot

- Information

- Key Products

- Facilities

Production Facilities

-

1-ton melting furnace

1-ton melting furnace

-

Automatic system

Automatic system

-

Pumping device and mold conveyor

Pumping device and mold conveyor

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR