CASTING

주조

JIREH PRECISION SEALS LTD.

- Information

- Key Products

- Facilities

Founded in 2016, JIREH PRECISION SEALS LTD. is a small giant in the field of floating seal that produces the lower running device of caterpillars for construction machinery, such as excavators and bulldozers, and the TBM (tunnel boring machine) and mining truck (axle) parts. With domestic and international excavator and dozer suppliers as customers, the company is striving to expand sales in the Chinese market, which is a market for heavy equipment parts, by increasing cost competitiveness.

The company has excellent technological competence designated as a Ppuri Technology Specialized Company (Korea National Ppuri Industry Center) in 2021, and won five patents for the method to manufacture floating seal using special release agent, etc. Having secured competitiveness based on the five patented technologies and the designation as a Company with Excellent Technological Competence Grade T4 (Korea Enterprise Data) in 2021, the company aims to expand sales by 200% each year through production facility expansion based on outstanding quality.

Information

- Address

- 35-11, Jamsil-gil, Seonghwan-eup, Seobuk-gu, Cheonan-si, Chungcheongnam-do, Korea

- Fax

- Website

- http://jirehseal.co.kr

Products

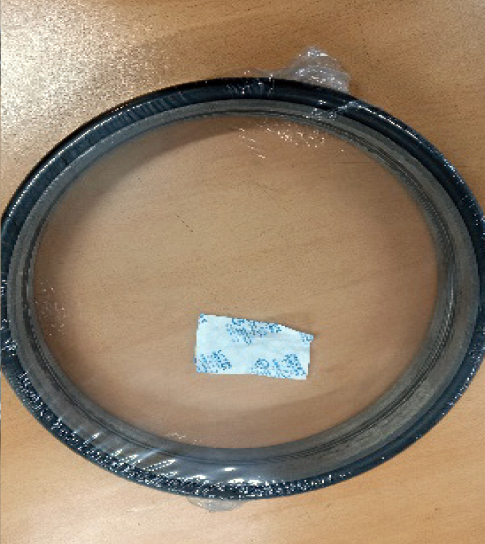

Floating seal for drive motor of heavy construction equipment

Certifications

ISO 9001, Venture Business, Ppuri Technology Specialized Com- pany, Company with Excellent Technological Competence, the company affiliated R&D Center

Production Facilities

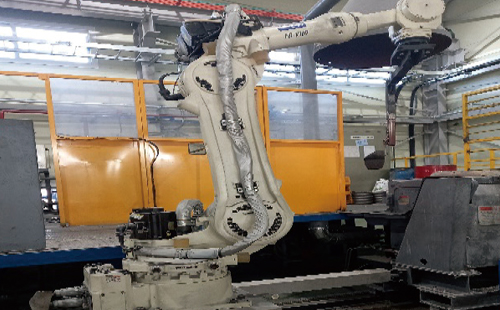

Electric melting furnace, robot centrifugal casting system, mold grinder, grinding machine, wrapping machine, polishing machine, vision system

Ppuri Technologies

Diecasting of cast iron

History

-

2016 JIREH PRECISION SEALS LTD. founded (Daegu)

2017 Won ISO 9001 quality system certification

2018 Relocated the plant (Asan, Chungcheongnam-do)Won venture business certification (Tech Safe System) Registered patent (f/seal centrifugal casting mold and its manufacturing method)

2019 Registered patents (carbon supply device for automatic casting system, centrifugal casting equipment and its manufacturing method)Established technological R&D Center (KOITA)

2020 Established smart factory MES Registered patent (method to manufacturing floating seal using special release agent) Applied automatic robot system to centrifugal casting pro- cess

2021 Designated as a Ppuri Technology Specialized Company (KPIC) Selected as an excellent technology company T4 grade (Korea Enterprise Data)

2022 Expanded and relocated the plant (Cheonan, Chungcheongnamdo)

Business Details and Production Items

By using robots and automatic injection system through a link to electric furnace and centrifugal casting equipment, Jireh Precision Seals not only secures workers’ safety, but also improves product quality based on fixed amount injection. At the same time as improving productivity and reducing labor cost through automation of the post-treatment process consisting of inner diameter grinding, taper grinding, sealing surface wrapping, and sealing surface polishing, the company responds to customers’ need for cost reduction and strives to secure quality and cost competitiveness.

Features

Securing optimal design and production technologies for ultra large scale metal face seal production through research on product design variables to improve product performance and enable manufacturing based on the compact product shape design for ultra large scale metal floating seal production using centrifugal casting technique

- Information

- Key Products

- Facilities

Key Products

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR