DIE&MOLD

금형

BKM

- Information

- Key Products

- Facilities

BKM was founded in 2011 by Yu Jae-hwa, a master craftsman for molding technol- ogy, under the corporate philosophy to achieve customer satisfaction through high product and delivery quality based on trust. Having secured the manufacturing infrastructure through the Mold Division, the company established a foundation for its business by attracting key global customers in various fields including automobile. Since 2017, the company has delivered the special semiconductor pipe, which it developed using the company’s own technique based on precision molding and injection technologies, to SK Hynix.

In 2020, BKM launched the Renewable Energy Division. Based on the expertise and experience that BKM has accumulated so far, it has started a new challenge with innovative and differentiated items in the renewable energy market.

Information

- Address

- Head Office: 72, Jikji-daero 456-beongil, Heungdeok-gu, Cheongju-si, Chungcheongbuk-do, Republic of Korea

- Tel

- +82-43-265-1311

- Fax

- Website

- http://www.bkm.co.kr

Products

Special pipe for semiconductor process, precision mold

Certifications

ISO 9001, ISO 14001, Knowledge Property Management Enterprise, INNOBIZ, Venture Business, Global IP Star Company, Ppuri Technology Specialized Company, FM 4910

Production Facilities

CNC machining center, CNC discharge machine, surface grinding machine, injection molding machine, 3D measuring system, etc.

Ppuri Technologies

Multi-material injection/press molding technology

History

-

2011 Company founded (Mold Division)

2014 Opened the Cheongju plant

2015 Established the company-affiliated R&D Center Acquired ISO 9001, ISO 14001, UL 94 certifications

2017 Completed development of special pipe for semiconductor process Commenced delivery of special pipe for semiconductor process (SK Hynix)

2020 Selected for the Ministry of SMEs and Startups overseas certification standard technology development project Selected for the Ministry of SMEs and Startups technolo- gy innovation project (for market response)

2021 Acquired INNOBIZ certification, Ppuri Technology Specialized Company certification, Materials, Parts, and Equipment Specialist certification, Knowledge Property Management Enterprise certification, approval for business restructuring from the Ministry of Trade, Industry and Energy (Al fuel cell solution), designation as Chungcheongbuk-do Star Company, Top Prize at the Hydrogen Mobility Show H2 Innovation Awards, Citation of the Ministry of SMEs and Startups for technological innovation, Hong Dae-yong Patent Technology Award from the Korean Intellectual Property Office, Citation of the Minister of Trade, Industry and Energy

2022 Designated as Global IP Star Company

Business Details and Production Items

Special pipe for semiconductor process

· Developing differentiated solutions for semiconductor process safety based on precision molding technologies and experiences

· Fundamentally addressing issues with the existing coating/lining method, which does not prevent corrosion caused by semiconductor toxic substances

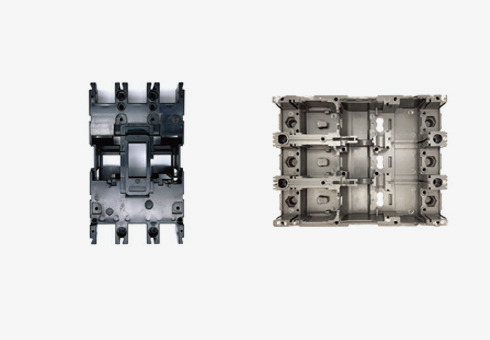

Precision mold

· Providing mold solutions to meet any customer need based on the top-tier precision mold design and manufacturing tech- nologies in the industry accumulated over many years

Features

Special pipe for semiconductor process

· Pinhole Free - Fundamentally preventing corrosion caused by pinholes

With technique to form chemical resistant coating on metal surface, pinhole generation is caused by outgassing and foreign materials, etc.

With compression/injection molding technique, high-quality chemical resistant coating is formed to fundamentally prevent factors causing pinholes

· Easy Work - Drastically improving handling quality and workability with high-quality coating formed through ultra high pressure compression/injection molding

- Information

- Key Products

- Facilities

Key Products

Automobile molds

Industrial molds

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR