DIE&MOLD

금형

TAESUNG PRECISION

- Information

- Key Products

- Facilities

TAESUNG PRECISION is a specialized manufacturer of press molds for sheet metal processing, such as progressive and transfer, and is capable of all processes from mold design, manufacturing, inspection, and try-out. In addition to the 2D and 3D design capabilities that determine the quality and function of molds, the company has CNC equipment as well as 300 ton, 500 ton (hydraulic), 1,200 ton test presses and 2,000 ton mass production presses for complete production simulation, quality assurance and the company is realizing the high quality and precision of the final product through the latest equipment including 3D Capability Maturity Model (CMM).

The company is constantly investing in human resource development to nurture engineers and field production personnel with years of experience and knowhow in each field. As a result of faithful efforts in the press mold field based on these facilities and manpower, the company has been recognized as the best mold supplier by leading Korean big companis with sales growth every year and mold quality and technology recognized by customers. Taesung Precision is establishing itself as a professional global standard mold supplier and a faithful partner for its customers through continuous investment and technological development.

Information

- Address

- Changwon plant: 67, Yeondeok-ro 15-beongil, Seongsan-gu, Changwon-si, Gyeongsangnam-do, Republic of Korea

- Tel

- +82-55-274-3580

- Fax

Products

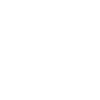

Automobile seat rail, refrigerator out door, washing machine cover cabinet, top plate, etc.

Certifications

ISO 9001, Hyundai Motor Company SQ

Production Facilities

MCT, milling machine, radial machine, polishing machine, press, etc.

Ppuri Technologies

Fine forming press molding technology

History

-

1987 TAESUNG PRECISION founded

1989 Started transaction with LG Electronics as a mold supplier

1996 Developed automobile seat rail mold

2002 Introduced 3D CAD (Unigraphics) system

2005 Installed press & CNC equipment and 3D measuring machine (CMM) Designated as a Ppuri Technology Specialized Company

2012 Converted to a corporation under Taesung Precision Co.,Ltd.

2015 Built second plant in Haman

Business Details and Production Items

Focusing on mold manufacturing to produce rail, an automobile seat part, and exterior items of home appliances (refrigerator, washing machine) based on mold design processing/assembly technology

Features

- Information

- Key Products

- Facilities

Key Products

-

SEAT

SEAT

-

REFRIGERATOR

REFRIGERATOR

-

WASHING MACHINE

WASHING MACHINE

- Information

- Key Products

- Facilities

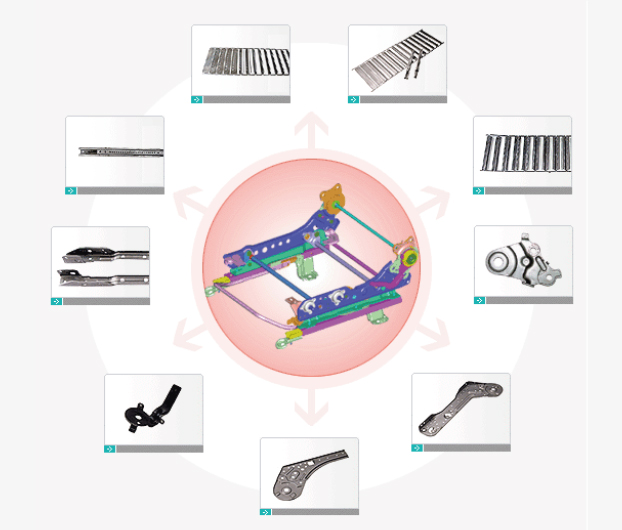

Production Facilities

-

2,000-ton press

2,000-ton press

-

1,600-ton press

1,600-ton press

-

1,200-ton press

1,200-ton press

-

Machining center-12

Machining center-12

-

Milling machine-5

Milling machine-5

-

Radial drilling machine

Radial drilling machine

-

3D scanner

3D scanner

-

Surface grinding machine

Surface grinding machine

-

Grinding machine

Grinding machine

-

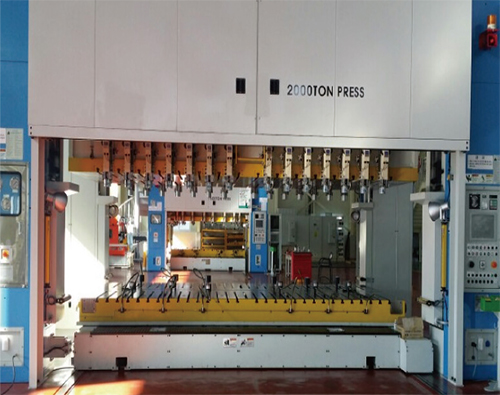

Wire cutter

Wire cutter

-

Projector

Projector

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR