DIE&MOLD

금형

TOOL & MOLD

- Information

- Key Products

- Facilities

Founded in 1996, TOOL & MOLD is striving to produce innovative ideas, develop advanced technologies, and achieve customer satisfaction in order to become a leader in the mold base market. The company is also capable of custom manufacturing through its facility investment to diversify the range of production scale from small to medium to medium to large-scale products.

In addition, to more effectively meet the needs of domestic and overseas customers, Tool N Mold is building a base for advancement to a total mold solution provider.

Information

- Address

- 92-72, Bamdui-gil, Paltan-myeon, Hwaseong-si, Gyeonggi-do, Republic of Korea

- Tel

- +82-31-366-1577

- Fax

- Website

- http://www.toolnmold.co.kr

Products

Mold base, diecasting base, finishing, mold export

Certifications

The company-affiliated R&D Center, Excellent Company in Risk Assessment, Quality Management System

Production Facilities

Such as for surface grinding, polishing, NC, finishing

Ppuri Technologies

High-speed mold manufacturing technologies

History

-

Oct. 1996 Myeongjin Industry founded

Oct. 2001 Converted to a corporation under Myungjin Industry Co., Ltd.

Mar. 2006 Manufactured mold base

Mar. 2011 Started shape and panel finishing

Nov. 2014 Changed company name to Tool N Mold

May. 2015 Won certification on the company-affiliated R&D Center

Apr. 2019 Built and relocated to the new plant in Hwaseong

Mar. 2021 Designated as a Ppuri Technology Specialized Company

Business Details and Production Items

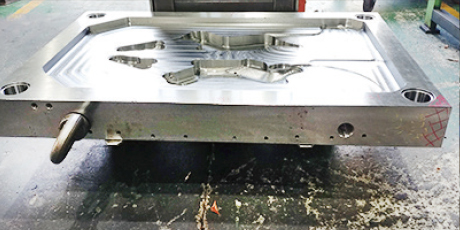

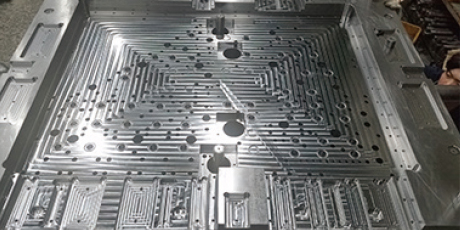

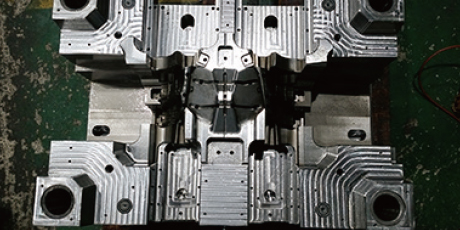

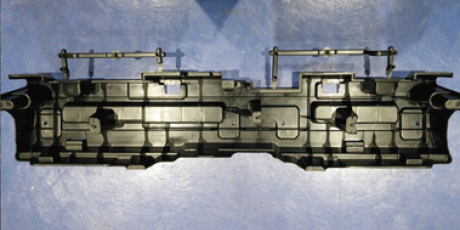

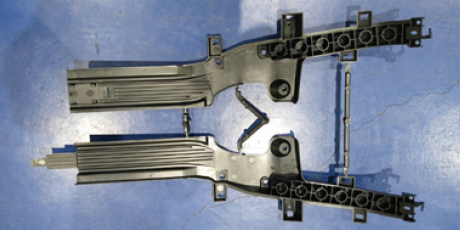

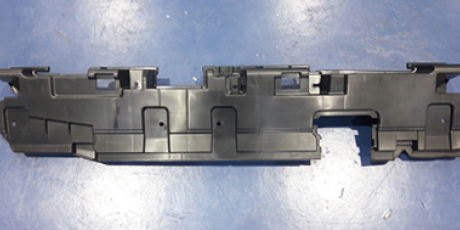

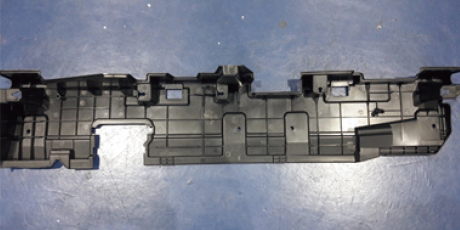

Mold base, diecasting base: Standard-type and order manufacturing of automobile/electronic appliance parts Finishing: Top and bottom plates and other related panels, part cores

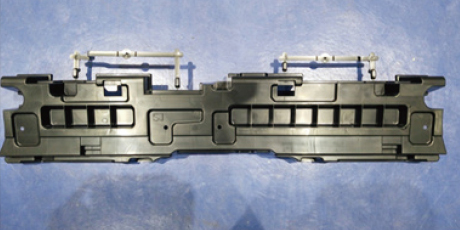

Mold export: Automobile plastic injection molds

Features

Total solution for mold: Tool N Mold provides all services, such as mold base manufacturing, finishing, and mold production, swiftly and accurately according to customers’ needs for fast delivery, high quality, and cost efficiency, etc.

Shape processing using 3D CAD/CAM: Tool N Mold provides shape processing service in the highest quality and shortest time based on the accurate data obtained from 3D CAD/CAM system.

- Information

- Key Products

- Facilities

Key Products

Mold Base / Die Cast Base

Finishing

Mold

- Information

- Key Products

- Facilities

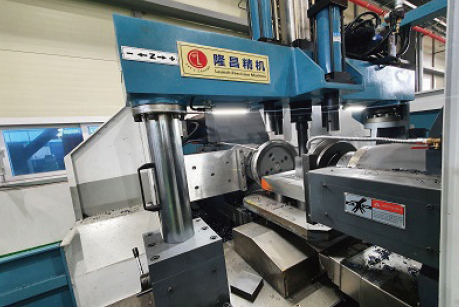

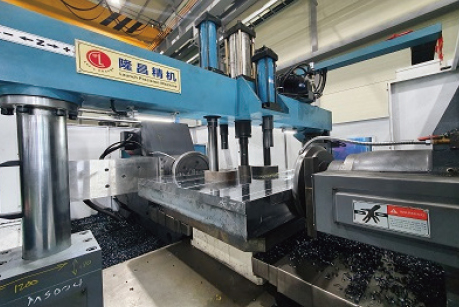

Production Facilities

-

Surface grinding facility

Surface grinding facility

-

Surface grinding facility

Surface grinding facility

-

Surface grinding facility

Surface grinding facility

-

Surface grinding facility

Surface grinding facility

-

NC facility

NC facility

-

NC facility

NC facility

-

NC facility

NC facility

-

NC facility

NC facility

-

Wood bobbin auto beveller

Wood bobbin auto beveller

-

Wood bobbin auto beveller

Wood bobbin auto beveller

-

Wood bobbin auto beveller

Wood bobbin auto beveller

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR