METAL FORMING

소성가공

KUN YOUNG METAL

- Information

- Key Products

- Facilities

Founded in 2009, KUN YOUNG METAL produces bolts, buts, and cold forging items that are used in automobile and other industrial fields based on the technological power and expertise built through continuous R&D. Having achieved growth especially through the production of long bolts for electric vehicle battery assembly, the company promotes to advance to a next level by developing and delivering forging items used for battery assembly.

Kun Young Metal is growing as a small giant equipped with excellent technological power and ability to satisfy customers.

Information

- Address

- 55, Myeongdongsandanan-gil, Hallim-myeon, Gimhae-si, Gyeo- ngsangnam-do, Korea

- Tel

- +82-55-335-6160

- Fax

- Website

- http://www.건영금속.kr

Products

Bolts, nuts, rivets, etc.

Certifications

IATF 16949

Production Facilities

Bolt former, header, rolling machine, vision sorting machine

Ppuri Technologies

Ultra high precision multi-level cold forming technology

History

-

May. 2009 KUN YOUNG METAL founded (cold forging)

Oct. 2009 Supplied parts to Hyundai Motor Company as a 2nd tier supplier

Jul. 2010 Supplied parts to Hyundai Mobis a 1st tier supplier

Sep. 2010 Extended and relocated the plant (Sangdong, Gimhae)

Jul. 2012 Relocated the plant (Mokbang-ri, Sangdong-myeon, Gimhae)

Nov. 2012 Won ISO/TS 16949:2009 certification

May. 2014 Introduced former machine (5-level former)

Jan. 2015 Registered as a 2nd tier supplier of LG Chem for electric vehicle battery

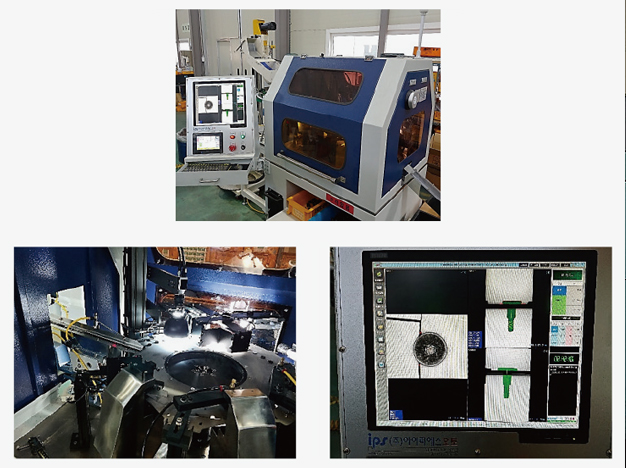

Jun. 2018 Introduced 2 vision inspection machines (screws, bolts, nuts)

Oct. 2018 Won IATF 16949:2016 certification

May. 2019 Supplied part to LG Electronics as a 1st tier supplier(distributor)

Feb. 2020 Installed measuring room, built smart factory

Jul. 2021 Extended and relocated the plant (Gimhae Myeongdong General Industrial Complex)

Business Details and Production Items

· Focusing on the manufacturing of bolts and nuts for electric vehicle battery pack assembly, Kun Young Metal achieves cus- tomer satisfaction by simplifying follow-up processes and reducing cost based on excellent forming technology

· Secured reliability by introducing vision inspection system

· Established smart factory, won customers’ trust by increasing speed/accuracy through link to MES

Features

Promoting prevention of defects through accurate verification of causes based on data link to vision inspection system for key products

Improving quality control level and reducing defect rate by obtaining accurate measurements

- Information

- Key Products

- Facilities

Key Products

-

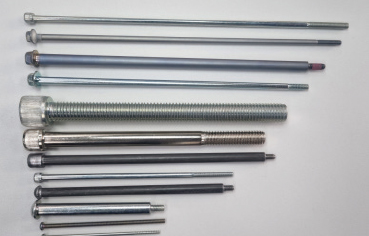

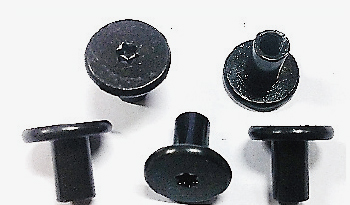

Bolts

Bolts

-

Nuts

Nuts

-

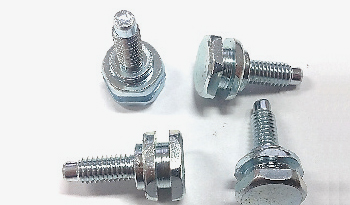

Wrench bolts

Wrench bolts

-

Long bolts

Long bolts

-

TS Bolts

TS Bolts

-

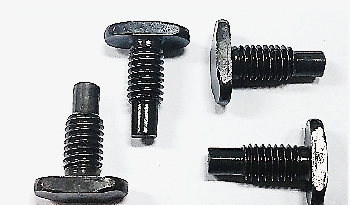

HT bolt

HT bolt

-

L-type anchor

L-type anchor

-

Wedge anchor

Wedge anchor

-

-

-

-

-

-

-

Electric vehicle battery parts

Automobile parts

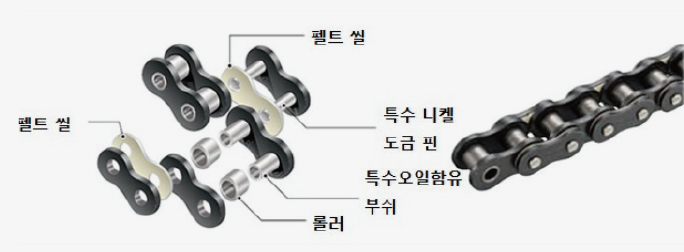

For conveyor chain

- Information

- Key Products

- Facilities

Production Facilities

-

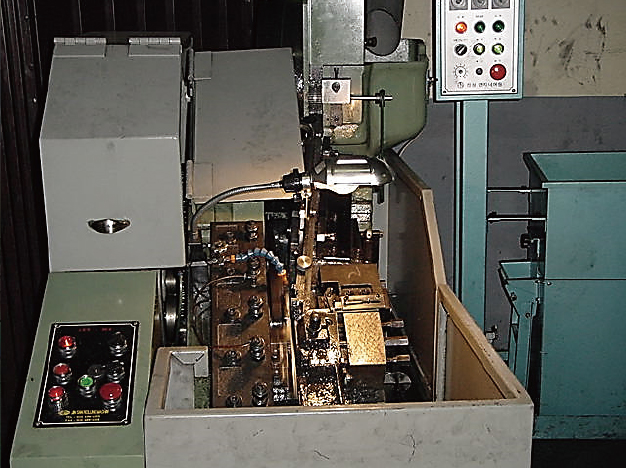

FORMER M/C

FORMER M/C

-

HEADER M/C

HEADER M/C

-

ROLLING M/C

ROLLING M/C

-

Vision inspection system (3 for bolts/1 for nuts)

Vision inspection system (3 for bolts/1 for nuts)

-

Vision inspection system (3 for bolts/1 for nuts)

Vision inspection system (3 for bolts/1 for nuts)

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR