METAL FORMING

소성가공

MYONGIN WIRE ROLLING

- Information

- Key Products

- Facilities

Founded in Gimpo in 2006 by a CEO with more than 40 years of experience in the same type of technology, MYONGIN WIRE ROLLING has grown based on its unique cold-rolling technology and know-how. Having secured a number of shape rolling technologies over the last several years, the company develops and produces materials used in various industrial fields, such as for automobile T/M snap ring, automobile parts, environmental filters, vessel structures, electronic device structures, linear-motion guard rail, spring rolling, and medical instrument parts.

While focusing on the development of cold rolling technologies and human resources for a wide range of materials, such as steel, stainless steel, nonferrous metal, and other special materials, Myongin Wire Rolling achieved cost reduction and quality improvement through investment in all areas of business management as well as facilities and technologies. Myongin Wire Rolling is achieving sustainable growth with a goal to become a company that is recognized for its excellent cold wire rolling products across the world.

Information

- Address

- Head Office: 3 Da 502, Sihwa Industrial Complex, 106, Mayu-ro 186-beongil, Siheung-si, Gyeonggi-do, Korea

- Tel

- +82-31-499-5010

- Fax

- Website

- https://mi-wiretech.co.kr

Products

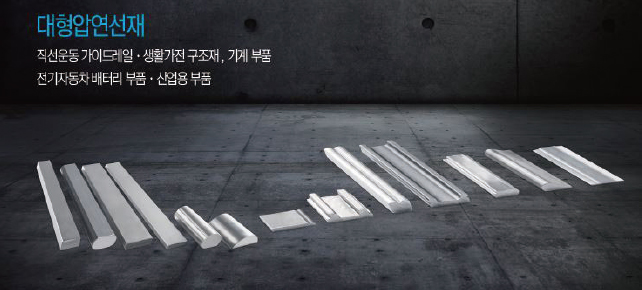

Large-scale cold rolling wire materials (vessel structures/home appliance structures/linear-motion guard rail, etc.) Medium-scale cold rolling wire materials (automobile parts/hy- draulic treatment filters, etc.) Small-scale cold rolling wire materials (p

Certifications

Materials, Parts, and Equipment Specialist, R&D Department, ISO 9001:2015, ISO 14001:2015, KITECH Partner, Small Giant, INNOBIZ, PPuri Technology Specialized Company, Youth-friendly Small Giant

Production Facilities

Φ 800 and Φ 520 7-continuous rolling machines, Φ 800 drive rolling machine, Φ 460 drive rolling machine, 3-continuous drive rolling machine, Φ197 drive rolling machine, Φ109 drawing roll- ing machine, Φ63 small-scale rolling machine, correction cutting machine, press cutting machine, automatic grinding machine

Ppuri Technologies

Roll Forming technology

History

-

Jun. 2006 Dong Bo Precision founded

Apr. 2014 Won certification as Tier 2 Supplier of Renault Samsung

Nov. 2016 Relocated Dong Bo Tech plant (Asan, Chungcheongnam-do), and changed company name

Nov. 2016 Won ISO/TS 16949 and ISO 14001 certifications

Sep. 2018 Won IATF 16949 certification

Nov. 2018 Established technological research institute

Jan. 2021 Mass production of cooling plate parts for Hyundai electric car Ioniq 5 battery

Mar. 2021 Applied for patent for electric vehicle battery cooling plate manufacturing technology

Mar. 2021 Won Ppuri Technology Specialized Company certification

Jul. 2021 Won INNOBIZ certification

Business Details and Production Items

Focusing on the manufacturing of cold rolling wire materials, the company supplies automobile T/M snap ring materials, en- vironmental filter materials, home appliance structure materials, vessel structure materials, linear-motion guard rail materials, materials for mechanical parts, precision electronic materials, spring materials, and materials for medical instrument parts.

Features

· Cold rolling for steel, stainless steel, nonferrous metals, special materials (Titanium, Duplex, Hastelloy, Monel, Super Alloy, etc.) · Product sizes ranging widely from 0.1 x 0.2 to 25.0 x 20.0 and 12.0 x 100

· Capable of developing items as materials for special purposes or special shapes with a high difficulty level

- Information

- Key Products

- Facilities

Key Products

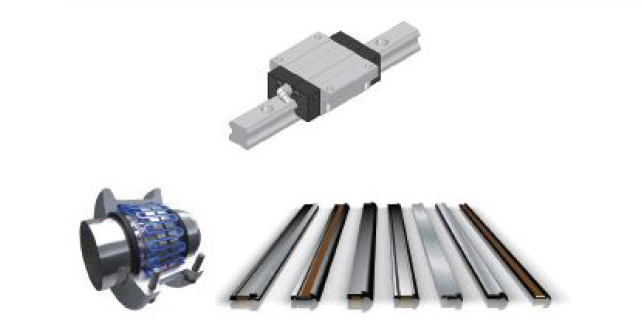

Electric vehicle battery parts

medium rolled wire

Small rolled wire

- Information

- Key Products

- Facilities

Production Facilities

-

Large-scale rolling production line

Large-scale rolling production line

-

Small and medium-scale rolling production line

Small and medium-scale rolling production line

-

Measuring equipment

Measuring equipment

-

Measuring equipment

Measuring equipment

-

Measuring equipment

Measuring equipment

-

Measuring equipment

Measuring equipment

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR