METAL FORMING

소성가공

WINDIA TECH

- Information

- Key Products

- Facilities

Windia Tech, a company manufacturing diamond tools, strives to provide excellent products by achieving the perfect technological and quality standard. The company is committed to achieving customer satisfaction by manufacturing high-quality products through continuous R&D and facility investment.

This is a small giant that dedicates the utmost effort to providing the best products swiftly by using high-quality raw materials.

Information

- Address

- 159, Gajaeul-ro, Bupyeong-gu, Incheon Metropolitan City, Korea

- Tel

- +82-32-575-0765

- Fax

Products

Diamond tools, special purpose machinery

Certifications

Production Facilities

Ppuri Technologies

Ultra high pressure/isostatic pressure shaping technology

History

-

Jul. 2001 Windia Tech established in Yongin-si, Gyeonggi-do

Oct. 2001 Commenced export to Japan and the U.S.

Jan. 2002 Won New Technology Developer by the Ministry of Trade, Industry and Energy

Mar. 2003 Commenced export to Southeast Asia and Europe

Sep. 2004 Established plant in China (Jinnan, Tianjin, China)

Aug. 2008 Additionally extended facility to manufacture 10,000 products per month

Jan. 2009 Won ISO 9001 quality management system certification

Mar. 2009 Registered R&D department

Jun. 2009 Selected as Technology Innovation Developer

Oct. 2011 Won Venture Business certification

May. 2012 Additionally extended production facility to produce all diamond polishing tools

Nov. 2014 Succeeded in localizing nonporous-type diamond & CBN wheel manufacturing using ceramic material

Jun. 2018 Relocated to new plant in Incheon Metropolitan City

Business Details and Production Items

· Wheel for Processing Hard-to-machine Materials: Using particles with high crushability High-efficiency Processing Wheel: High-speed continuous grinding, high continuous grinding effect, excellent processability

· Precision Processing Wheel: Can be used for dry processing, excellent abrasion resistance

· Wheel for Response to Automation: No chip fusion, excellent particle supporting power

Features

Diamond tool manufacturing specialist with advanced technological power

- Information

- Key Products

- Facilities

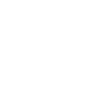

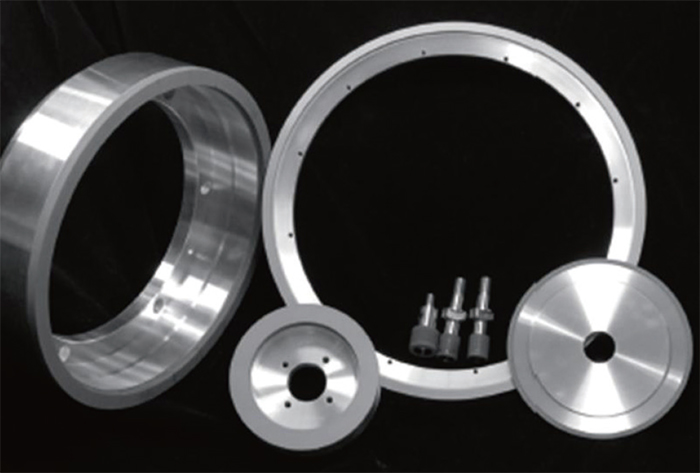

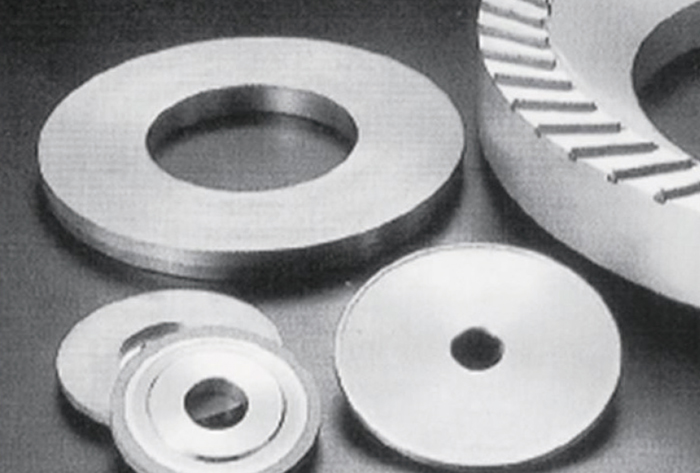

Key Products

-

Vitrified bond is a binding agent created by applying materials used for pottery and ceramic making. Applied to the manufacturing of products with high porosity, it lowers clogging and heat generation in the grinding process, and facilitates truing and dr

Vitrified bond is a binding agent created by applying materials used for pottery and ceramic making. Applied to the manufacturing of products with high porosity, it lowers clogging and heat generation in the grinding process, and facilitates truing and dr

-

Resin bond is a binding agent made by adding reinforcing and filling materials to synthetic resin, such as phenol resin. With excellent elasticity and low grinding resistance, this product ensures excellent surface roughness and satisfactory grindability.

Resin bond is a binding agent made by adding reinforcing and filling materials to synthetic resin, such as phenol resin. With excellent elasticity and low grinding resistance, this product ensures excellent surface roughness and satisfactory grindability.

-

Metal bond is a product made with a bronze-type metal powder as the binding agent. Made using powder metallurgic technology, this product ensures excellent hardness and abrasion resistant, and therefore is suitable for rough machining and grinding of vari

Metal bond is a product made with a bronze-type metal powder as the binding agent. Made using powder metallurgic technology, this product ensures excellent hardness and abrasion resistant, and therefore is suitable for rough machining and grinding of vari

-

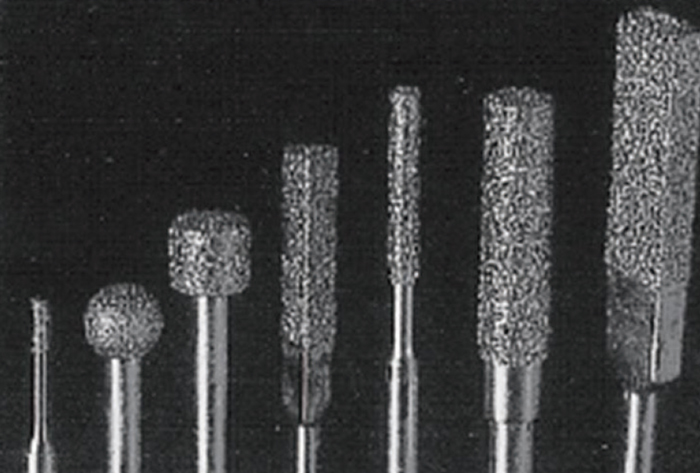

Electroplated bond is a binding technique using nickel through the application of electroplating technology. As the grits are electrodeposited by making a shank through mechanical processing, this technique can be applied to the manufacturing of complicat

Electroplated bond is a binding technique using nickel through the application of electroplating technology. As the grits are electrodeposited by making a shank through mechanical processing, this technique can be applied to the manufacturing of complicat

Vitrified Bond Diamond & CBN Wheel

Resin Bond Diamond & CBN Wheel

Metal Bond Diamond & CBN Wheel

Electroplated Diamond & CBN Tools

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR