METAL FORMING

소성가공

HANA TECH

- Information

- Key Products

- Facilities

Established in 1998, Hana Tech delivers materials and facilities for operation and maintenance to POSCO and power plants. The company’s key products are the RH dip tube (operation material) for refining outside the furnace at the steelmaking plant of Gwangyang Steel Mill, and the electrode casing (operation material) used for fixing SNNC electric furnace.

Since designation as a Venture Business in 2000, the company has been selected as a Promising SME in Jeollanma-do and a Small Giant in 2001 and 2021 respectively. While recording the annual sales of approximately KRW 20 billion, Hana Tech is achieving continued growth based on its technological competitiveness.

Information

- Address

- Plant 1: 1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeol- lanam-do, Korea

- Tel

- +82-61-772-7781

- Fax

Products

Metallic tube, ladle bottom bubbling, auto coupler, electrode casing, etc.

Certifications

ISO 9001, ISO 14001, ISO 45001, Promising SME, INNOBIZ, MAIN- BIZ, Venture Business, Small Giant, etc.

Production Facilities

Boring machine, milling machine, radial drill machine, shearing machine, cutting machine, hydraulic press, CO2 welding machine, argon welding machine, arc welding machine, etc.

Ppuri Technologies

Hot/cold composite shaping of steel materials

History

-

1988 Hana Tech established

2001 Registered as facility material supplier for POSCO E&C

2002 Won INNOBIZ certification

2003 Won Parts and Materials Specialist certification (Ministry of Trade, Industry and Energy No. 964)

2006 Registered as a company eligible for power generation facility maintenance (Korea Energy) Registered as a company eligible for maintenance (Korea East – West Power)

2010 Won POSCO Citation and the Best Prize for Performance Sharing Won POSCO Citation and the Best Prize for Open Innovation and Shared Growth

2012 Won POSCO Citation as QSS Powerhouse

2013 Won designation as an Excellent Convergence Technology Research Center for ATC project

2019 Won designation as a Promising SME (Jeollanam-do) and Venture Business certification

2020 Won MAINBIZ and INNOBIZ certifications

2021 Won designation as a Small Giant (Ministry of Employment and Labor) and Materials, Parts, and Equipment Specialist certification

Business Details and Production Items

· Metallic Tube

This product is used in the RF facility for secondary refining in a steelmaking plant. The inside and outside areas are built to be castable in order to protect the tube from high-temperature molten steel. When a dip tube is submerged in the molten steel in ladle, and Ar is injected to the lifted tube, the molten steel is circulated according to the difference in the specific gravity of molten steel from the lowered rube. In this process, the molten steel is decarbonized, nonferrous inclusions are separated, and impurities, such as bubbles, are removed.

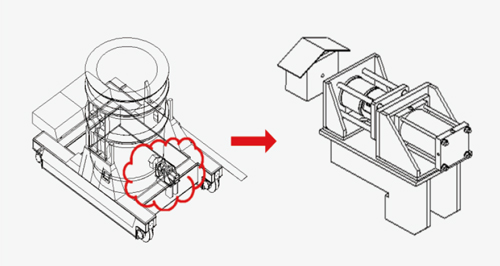

· SNNC - Ladle Bottom Bubbling (Auto Coupler) Development

The Fe-Ni mixing facility in bubbling process is installed in the bubbling and LF processes of SNNC refining plant. As Fe-Ni mixing is carried out through automatic injection of nitrogen gas into the ladle, the properties are homogenized. Contributing to quality improvement in premium steel manufacturing, this facility reduces process time and prevents accidents affecting workers.

· SNNC - Electrode Casing

An electrode is inserted to the casing, and ferronickel and subsidiary materials are inserted in between the electrode and casing. Then, Fe - Ni mixture is added to the electric furnace, high-temperature electricity is generated using the electrode to melt the mixture, and it is used to produce the Fe - Ni products.

Features

Since establishment, Hana Tech has supplied tubes and other processing items to POSCO, SNNC, and power plants. Having ac- cumulated technological power for pipe refining and processing, the company has expanded its business area to automatic facility design, manufacturing, and installation.

- Information

- Key Products

- Facilities

Key Products

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR