WELDING

용접

SAMHONG MACHINERY

- Information

- Key Products

- Facilities

SamHong Machinery specializes in the processing and manufacturing of industrial machinery and medium to large-size machines. Based on its technological power and expertise built through many years, the company manufactures products through precision processing, such as vessel engine and pump, international thermonuclear experimental reactor (ITER), engineering machinery, and other industrial machinery.

Having obtained the ISO 9001 and ISO 14001 quality management system certifications as well as the certification of electric power industry technological standard for nuclear power plants, SamHong Machinery leads precision machinery industry with its top-tier quality and technological competitiveness.

Information

- Address

- Head Office: 308, Beopsu-ro, Beopsu-myeon, Haman-gun, Gyeo- ngsangnam-do, Korea

- Tel

- +82-55-583-8024

- Fax

- Website

- http://www.shemc.co.kr

Products

Onshore and offshore engine parts, compressor parts, pump parts, power plant parts, engineering machinery and industrial machinery parts, vacuum chamber, nuclear fusion experimental reactor, etc.

Certifications

ISO 9001, ISO 14001, INNOBIZ, KEPIC-MIN, the company-affiliated R&D Center, Strategic Industrial Technology Standard, Clean Workplace

Production Facilities

Large-scale five-side processing machine (Plano Miller), large- scale floor boring machine, turning and milling machine

Ppuri Technologies

Welding technology for key plant materials

History

-

1995 SamHong Machinery established

1999 Registered as tier 1 supplier for Doosan Heavy Industries(nuclear field)

2022 Commenced engineering machinery business, registered as tier 1 supplier for Hyundai Wia

2003 Commenced offshore/onshore business, registered as tier 1 supplier for STX

2005 Won ISO 9001 certification

2008 Won ISO 14001 certification

2013 Participated in ITER project, received order for thermalshield manufacturing and installation

2014 Completed production plant (Samhong, Plant 2)

2015 Won and renewed KEPIC-MN/SN certification

2016 Commenced vacuum chamber business for display (FDP)production

2020 Commenced SMR business, registered as a partner for KAERI and KHNP

2022 Converted to corporation

Business Details and Production Items

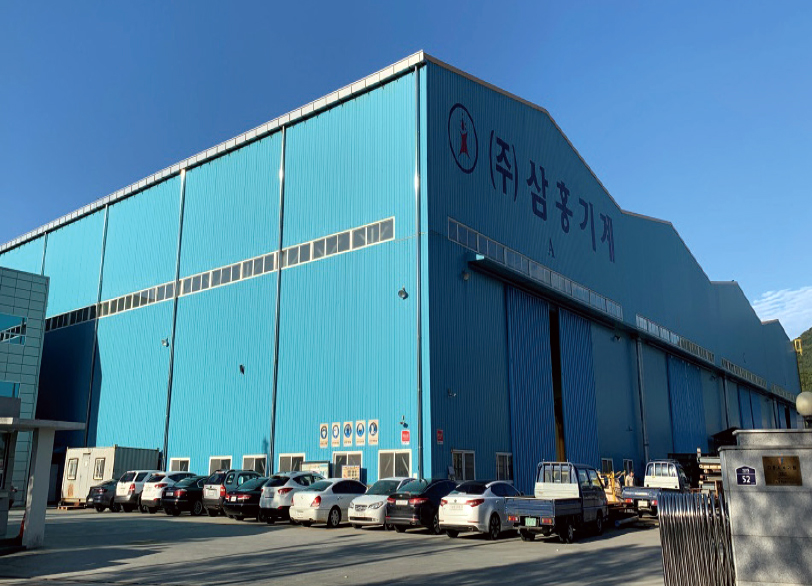

· Offshore and Onshore Engine Parts: Engine block and crank case (2 strokes & 4 strokes)

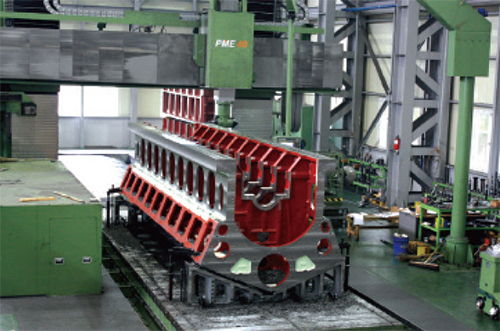

· Compressor Parts: Compressor frame, compressor bedplate, compressor flywheel

· Pump Parts: Pump casing and pump bed

· Power Plant Parts: Cask, tube sheet, top plate

· Engineering Machinery and Industrial Machinery Parts, Vacuum Chamber: Bed, frame, vacuum chamber

· ITER: Thermal shield

Features

· Technology (Human Resources): Approx. 10 highly qualified persons with nuclear power plant manufacturing experience of over 30 years - Personnel to develop equipment for manufacturing parts, which are small quantity batch production items

· Manufacturing Facility: Small reactor and nuclear fusion facility - Plant and facilities optimized to manufacturing/processing

· Certification: KEPIC-MN/SN for nuclear quality guarantee - Unable to manufacture nuclear items without KEPIC certification

· Technology: Technological personnel with accumulated experiences and expertise

- Information

- Key Products

- Facilities

Key Products

-

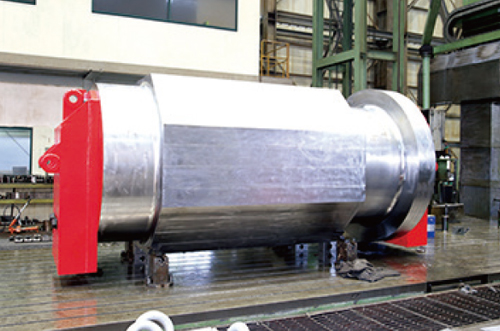

Offshore and onshore engine parts

Offshore and onshore engine parts

-

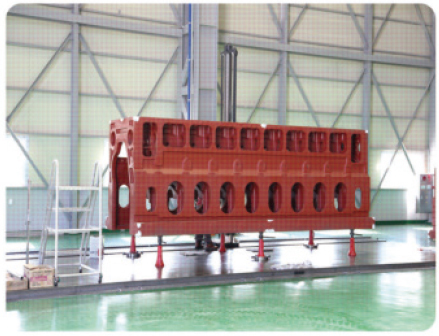

Compressor parts

Compressor parts

-

Pump parts

Pump parts

-

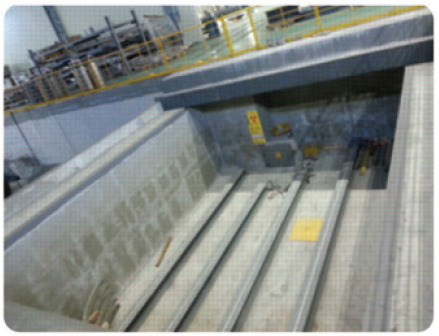

Industrial machinery, mechanical parts, vacuum chamber

Industrial machinery, mechanical parts, vacuum chamber

-

Power plant parts

Power plant parts

- Information

- Key Products

- Facilities

Production Facilities

-

HF 5M

HF 5M

-

HF 5M

HF 5M

-

HF 7M

HF 7M

-

Marking Machine

Marking Machine

-

HPM 30L

HPM 30L

-

HF 3M

HF 3M

-

Silver Coating Line

Silver Coating Line

-

RT Room (NDT)

RT Room (NDT)

-

RB4N-4M

RB4N-4M

-

RB4N-7M

RB4N-7M

-

CNC TiltingTable

CNC TiltingTable

-

Vertical Milling & Lathe

Vertical Milling & Lathe

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR