WELDING

용접

NKS

- Information

- Key Products

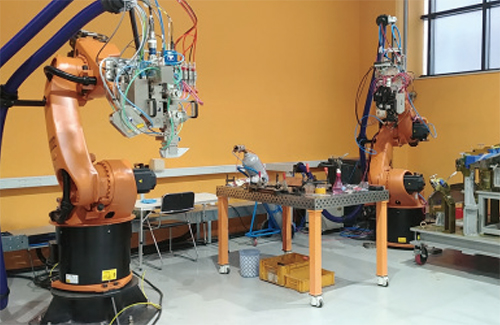

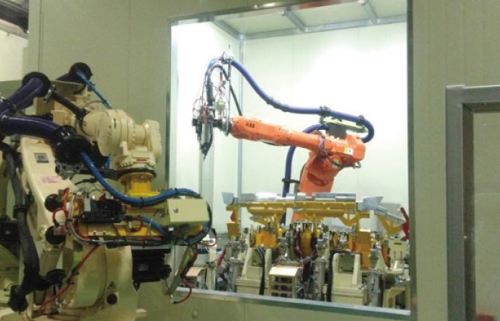

- Facilities

NKS is an innovative company in laser engineering field that focuses on the development of advanced technologies for automobile, heavy industry, and electrical and electronic industries. NKS specializes in the development and manufacturing of jigs and laser facility and welding system establishment in addition to consulting for new technologies in relation to welding and joining for application across industrial sectors.

The company is equipped with a state-of-the-art system for development into a leader in automobile industry through continuous R&D, facility investment, and management innovation. NKS is broadening its marked by partnering with major companies in Korea and abroad. At the same time, it is promoting growth by expanding the area of new technologies targeting not only major companies in Korea, but also overseas customers.

Information

- Address

- #310, 273-20, Gaejwa-ro, Geumjeong-gu, Busan Metropolitan City, Korea

- Tel

- +82-51-668-5161

- Fax

- Website

- http://www.nkskorea.com

Products

Laser welding, TWB welding, hybrid laser welding, laser cladding, laser brazing, scanner laser welding, laser cutting, laser cleaning

Certifications

Venture Business, ISO 9001, ISO 14001, Company with Excellent Technological Competence

Production Facilities

Ppuri Technologies

Remote control welding system technology

History

-

Mar. 2010 NKS established, registered business license

Oct. 2010 Registered as a partner for Trumpf Engineering, Germany

Jun. 2011 Won Venture Business certification

Sep. 2011 Established the company-affiliated R&D Center

Jun. 2012 Entered into partnership agreement with MicroLoc, U.K.

Oct. 2017 Registered as a partner for and entered into partnership agreement with Coherent Engineering, U.S.

Oct. 2018 Registered as tier 1 supplier of Hyundai Motor Company

Jul. 2020 Registered as tier 1 supplier of Doosan Heavy Industries

Business Details and Production Items

· Laser Welding: High-density laser is concentrated on a point through an optical lens, and material is heated and melted for joining using the instant energy increase.

· TWB Welding: TWB stands for tailor welded blank. Materials of different types in varying thickness or hardness are cut into an appropriate size, and welded using laser into a final shape.

· Hybrid Laser Welding: This is a high-efficiency and premium welding technique to supplement the weakness of welding using single heat source as laser and arc are used in combination.

· Laser Cladding: This is a process technology to add filler material, which is a different metal from the target material, on the surface on the target material, and melt the filler material using laser beam.

· Scanner Laser Welding: High-speed laser welding is possible within the area of laser beam irradiation on the scanner. Productivity is considerably improved as only product moving is conducted by jig.

· Art Cladding: High-output laser beam is irradiated on the metal surface to instantly melt the surface, and metal powder is also supplied concurrently for real-time cladding. The technique is similar to 3D printing.

· Laser Cutting: As a type of separation using heat, this process is to cut metal and nonmetal materials of diverse thicknesses.

Features

Laser engineering for across industrial sectors

- Information

- Key Products

- Facilities

Key Products

-

Laser welding

Laser welding

-

Hybrid laser welding

Hybrid laser welding

-

Laser blazing

Laser blazing

-

Scanner laser welding

Scanner laser welding

-

Art cladding

Art cladding

-

Laser cutting

Laser cutting

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR