WELDING

용접

PNS

- Information

- Key Products

- Facilities

Established in 1988, PNS has continuously promoted change and innovation over the last 34 years. Under the corporate philosophy to contribute to people and the society, the company has accumulated differentiated technological power.

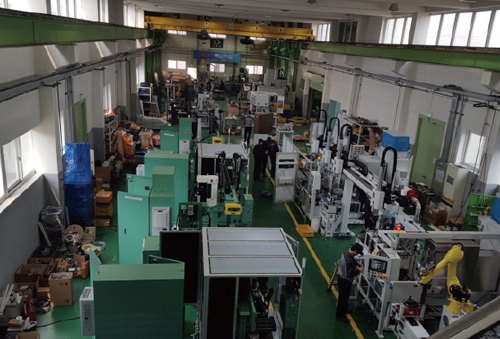

By using the technologies, it produces plant automation equipment, electronic beam and laser welding automation equipment, machine vision, and nondestructive ultrasonic inspection automation equipment, etc. for the industrial fields of automobile, electrical and electronic, semiconductor, and secondary cell.

Responding to customer needs in all areas from R&D to production, PNS is growing as a leading company to achieve the highest customer satisfaction.

Information

- Address

- Head Office: 25-11, Majeon-gil, Gunnae-myeon, Pocheon-si, Gyeonggi-do, Korea

- Tel

- +82-31-538-6500

- Fax

- Website

- http://www.pnscorp.kr

Products

Plant automation equipment, welding (electronic beam/laser) automation equipment, machine vision inspection equipment, ultrasonic inspection equipment, high-speed balancing machine, robot welding system

Certifications

ISO 9001, ISO 14001, INNOBIZ, Promising SME, SQ, Promising Export Company

Production Facilities

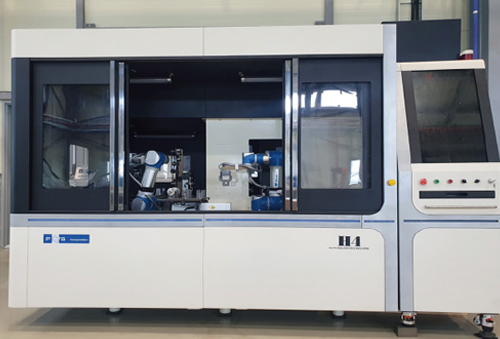

Electronic beam welding machine, welding – inspection automation line equipment, machining center, CNC lathe, milling machine, grinding machine

Ppuri Technologies

Low-cost, high-durability, low-defect vacuum welding technology

History

-

1988 Dongbang Precision Machinery established

1999 Changed company name to PNS, registered as tier 1 supplier of HMC/KMC

2005 Won ISO 9001 and ISO 14001 certifications

2010 Established technological research institute Won INNOBIZ and Promising SME of Gyeonggi-do certifications

2012 Selected as Small Giant

2019 Won HKMC supplier quality assurance SQ (welding) and certification as Good Company of Gyeonggi-do

2020 Completed Pyeongtaek Plant

2021 Won designation as Promising Export Company and Ppuri Technology Specialized Company

Business Details and Production Items

PNS manufactures welding (electronic beam, laser) automation equipment, machine vision inspection equipment, and ultrasonic inspection equipment for automobile transmission part production. Based on the plant automation equipment manufacturing technologies developed, the company has expanded its business area to include high-speed balancing machine and process automation using robot.

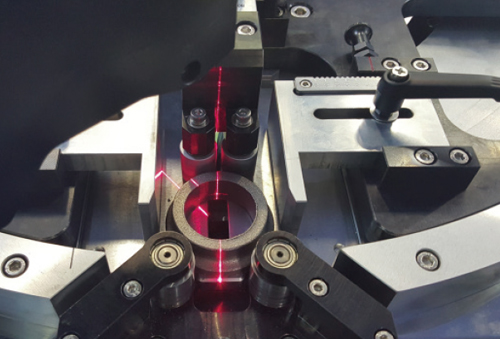

· Welding (electronic beam/lase) automation equipment

· Machine vision (3D laser scan) inspection equipment, ultrasonic testing equipment

· High-speed balancing machine

Features

· Secured advanced technologies for automation equipment manufacturing and system establishment, such as from electronic beam/laser welding part production to quality inspection, in automobile, electrical, and electronic fields

· Secured ten patents for ultrasonic inspection equipment and machine vision inspection equipment, etc.

· Secured high-quality human resources for hardware design and software (algorithm & program) development, equipped with technical personnel and manufacturing system to meet customer needs for production automation

- Information

- Key Products

- Facilities

Key Products

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR