SURFACE TREATIMENT

표면처리

PNT SAMIL INDUSTRY

- Information

- Key Products

- Facilities

As a company specializing in powder coating with approximately 20-year history, PNT SamIl Industry has secured differentiated technological power. Promoting innovative R&D for coating technology, replacement and extension of facilities, and use of eco-friendly paints without the six major heavy metals, the company realizes customer satisfaction by creating premium coating products based on its powder coating technological power.

Information

- Address

- 86, Jinheung-ro 38-beongil, Danwon-gu, Ansan-si, Gyeonggi-do, Korea

- Tel

- +82-31-497-3131

- Fax

- Website

- http://www.pntsamil.com

Products

Enclosure rack (shield box), ESS rack (electric battery box), semiconductor equipment, reflow

Certifications

ISO 9001, ISO 14001, ISO 45001, INNOBIZ, MAINBIZ, the company-affiliated R&D Center, 3 patents, 1 design registration, Environmental Certification (Green Grade), Excellent Company in Risk Assessment, Ppuri Enterprise, Enterprise Owned or Operated by Person with Disability, Small Giant, Youth-friendly Company (two years in a row), Ppuri Technology Specialized Company, Great Place to Work, Promising SME of Gyeonggi-do

Production Facilities

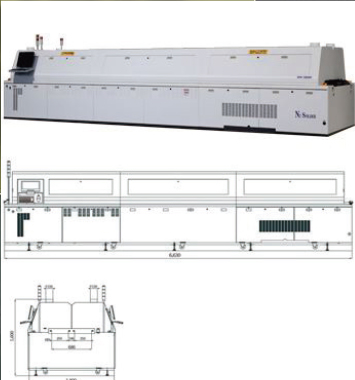

258m U-turn conveyor line, 258m U-turn automatic conveyor line (348 heavy objects), color measuring device, coating thickness measuring device, powder coating machine, etc.

Ppuri Technologies

Surface treatment technology to improve durability of interior and exterior parts

History

-

1998 PNT Sam Il Industry established

2005 Won ISO 9001:2001 and ISO 9001:2000 certifications

2010 Won quality certification from Rittal (supplier designation)

2013 Established R&D department

2016 Replaced and extended box oven line (direct heating forced convection-type coating booth) (No. 1: 12m in length, 4m in width, 4m in height) (No. 2: 8m in length, 4m in width, 4m in height)

2018 Extended automatic production lines 1 and 2 (Length: 258m * 2500 (L) x 2050 (H) x 1100 (W)) Established QMB (Quality Management Basic) system Won quality certification from Samsung SDI (QPA, QSA) (supplier designation)

2019 Won quality certification from Hyundai Electric (QPA, QSA) (supplier designation)

2020 Won quality certification from AM (Applied Materials) (supplier designation)

2021 Won quality certification from SEMES SQ and Hanwha (supplier designation) Won Ppuri Technology Specialized Company certification

Business Details and Production Items

PNT Sam Il Industry, a powder coating specialist, has improved adhesion of coating by automatically spraying paint following phosphate pre-treatment of the coating surface.

By automating the entire spray process through the application of electro- phoresis powder coating technique to ensure high corrosion resistance, the parameters, such as the amount of electrophoresis, output amount, and air pressure, are optimally adjusted.

Creating beautiful exterior, the high-temperature oven-drying tech- nique integrated with PID (proportional integral derivation) control technique enables to set the temperature and production speed according to the thickness of coating surface, and therefore prevent such defects and non-drying and excessive drying.

Features

While liquid coating is vulnerable to scratch, powder coating produces high durability that it does not peel off unless an impact in a level equivalent to hammering is applied.

PNT Sam Il Industry has created a corporate image to be environmental friendly by establishing a clean factory to promote low carbon and eco-friendly production as well as FEMS, a plant energy management system to ensure efficient energy use, and smart factory to improve productivity, quality, and customer satisfaction through the application of ICT combined with digital automation solutions.

- Information

- Key Products

- Facilities

Key Products

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR