SURFACE TREATIMENT

표면처리

SEBUM INDUSTRY

- Information

- Key Products

- Facilities

Established as a metal surface treatment company in 1999, Sebum has achieved growth each year, and won recognition for its technological power across the world by supplying products to major automakers and automobile parts suppliers overseas.

In particular, Sebum focuses on removing the causes of defects in order to achieve “zero defect rate,” and is improving process to prevent the leakage of defective products in the shipping stage.

The company is achieving customer satisfaction by accumulating various technologies and investing in advanced equipment. With a sprit to take on new challenges and the advanced technological power, Sebum is growing as a company respected by customers and the society.

Information

- Address

- 160, Seongseogongdannam-ro, Dalseo-gu, Daegu Metropolitan City, Kore

- Fax

- Website

- http://www.sebum.co.kr

Products

Soft anodizing, hard anodizing, coloring, chromate, processing/ deburring, surface treatment

Certifications

ISO 45001, the company-affiliated R&D Center, SQ, IATF 16949, Materials and Parts Specialist, Promising SME, ISO 14001, INNOBIZ, ISO 9001, ISO/TS 16949

Production Facilities

Rectifier, freezing machine, anti-pollution facility, electricity receiving facility, hoist, automation line, ultrasonic cleaning system, compressor, hot air dryer, filter, robot deburring machine, etc.

Ppuri Technologies

Surface treatment technology to improve durability of interior and exterior parts

History

-

1999 Sebum Chromate established

2002 Changed company name to Sebum

2004 Established fully automatic Al anodizing line

2005 Won Iso 9001 quality assurance system certification

2006 Registered G.M. DAT plant

2007 Established automatic Mg anodizing line, won INNOBIZ certification

2008 Established Sebum Surface Treatment R&D Center

2011 Won designation as a promising SME

2013 Established Plant 2 Completed ultrasonic system line Won ISO/TS 16949, ISO 14001, and KSQ certifications

2016 Won Materials and Parts Specialist certification

2018 Established Plant 3, established fully automatic Al anodizing line

2021 Established the company-affiliated R&D Center

2022 Won Iso 45001 certification, extended precision automatic robot deburring line 2

Business Details and Production Items

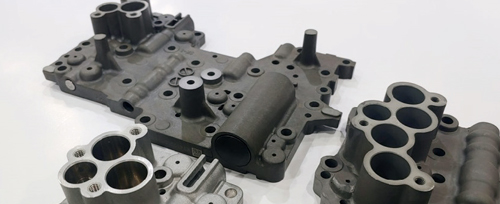

Soft Anodizing: Improving corrosion resistance, abrasion resistance, hardness, insulation, coating adhesion, radiation rate Hard Anodizing: Improving corrosion resistance, abrasion resistance, hardness, insulation

Coloring

Chromate: Excellent coating adhesion, corrosion resistance, dyeing possible

Processing/deburring Surface treatment

Features

- Information

- Key Products

- Facilities

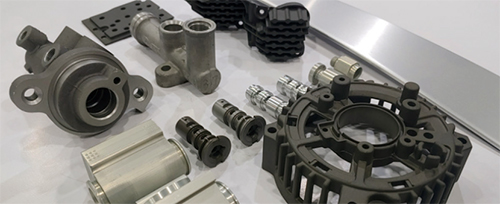

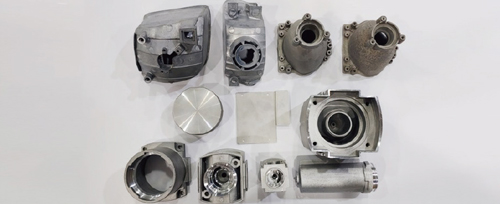

Key Products

-

Soft Anodizing

Soft Anodizing

-

Hard Anodizing

Hard Anodizing

-

Staining

Staining

-

Chromate

Chromate

-

Processing/deburring

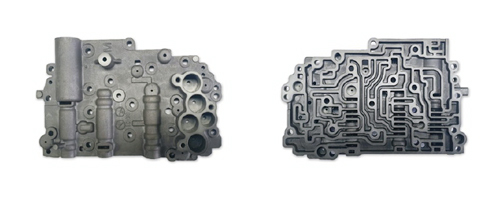

Processing/deburring

-

Surface treatment

Surface treatment

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR