HEAT TREATIMENT

열처리

FURNACE COREA

- Information

- Key Products

- Facilities

Specializing in the design and manufacturing of forced convection-type industrial furnaces, Furnace Corea supplies high-performance furnaces capable of swiftly responding to thermal load fluctuation at the same time as realizing rapid heating through application of forced convection technology.

Forced convection-type industrial furnace is a system where high-temperature combustion gas generated by burner is raised in pressure using a special heat-resistant fan.

Then, the gas collides into a work at the speed of 20 – 40m/sec to increase the temperature of the work. Centering on the forced convection-type industrial furnace manufacturing, the company provides high-quality solutions suitable for hot forging and heat treatment.

Information

- Address

- 42, Gunjacheon-ro 81-beongil, Siheung-si, Gyeonggi-do, Korea

- Tel

- +82-31-498-8345

- Fax

- Website

- http://www.furnacecorea.co.kr

Products

Heating furnace for light alloy forging, heat treatment furnace for light alloy, heating furnace for copper alloy forging, heat treatment furnace for steel, material alignment and feeding system

Certifications

Production Facilities

Ppuri Technologies

Surface hardening technology for aluminum alloy engine parts to reduce vehicle weight

History

-

1989 Keumwonsa entered into technological affiliation agreement with Furnace Chuku of Japan, commenced design and sale of forced convection-type industrial furnace

1998 Furnace Corea established through spinoff from Keumwonsa

1999 Registered as Hyundai Motor Company supplier, exported industrial furnace parts following registration of trade business with KITA

2003 Furnace Corea Co,. Ltd. established

2008 Built plant and relocated head office

2013 Established the company-affiliated R&D Center Won ISO 9001 certification

2014 Obtained patent for forced convection-type heat treatment, won Venture Business certification

2015 Won Three-million-dollar Tower of Export, won certification as an Excellent Company in Risk Assessment, relocated plant and head office

Business Details and Production Items

Forced convection-type industrial furnace does not use radiation heat. Rapid heating is achieved through an increase of the air speed up to a permitted level according to the physical properties using a super alloy fan. As for CO2 emission, this product reduces the amount by 2.5 - five times in comparison to those of other companies as it ensures energy efficiency by 65 - 75%.

Features

Furnace Corea supplies products through technological support from Furnace Chuku, which has secured a world-class patented technology to achieve rapid heat delivery with extremely high followability for thermal load fluctuation and temperature distribution close to the limit.

With the technological support, extension of energy for industrial furnace, space efficiency according to the decreased furnace body size, uniformization of temperature distribution, and increased facility lifespan are achieved.

- Information

- Key Products

- Facilities

Key Products

-

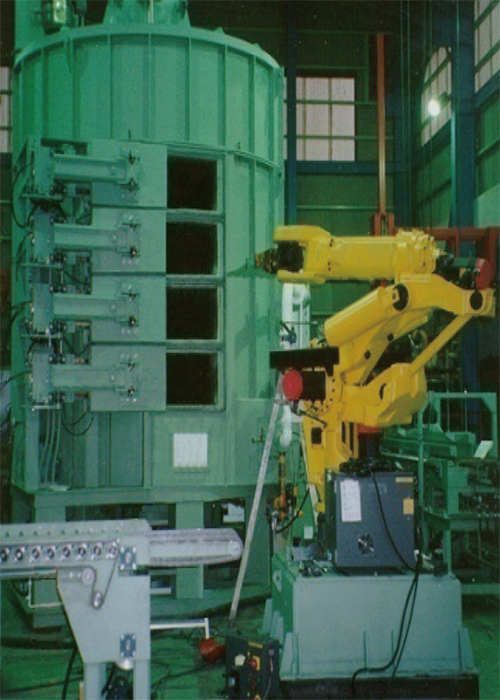

Forced convection-type light alloy forging treatment

Forced convection-type light alloy forging treatment

-

Forced convection-type light alloy heat treatment

Forced convection-type light alloy heat treatment

-

Forced convection-type copper alloy forging

Forced convection-type copper alloy forging

-

Forced convection-type steel heat

Forced convection-type steel heat

- Information

- Key Products

- Facilities

Production Facilities

-

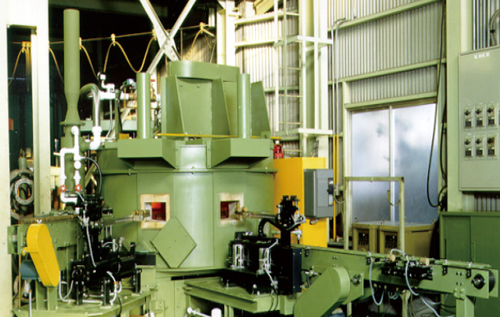

ACF furnace

ACF furnace

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR