HEAT TREATIMENT

열처리

KOREA INDUSTRY

- Information

- Key Products

- Facilities

Korea Industry specializes in the heat treatment of automobile, construction machinery, agricultural machinery, and other industrial machinery parts. Through quality control and management innovation based on continuous investment in and R&D for production, technology, and management, Korea Industry has established itself as a company trusted by customers.

Capable of heat treatment for small, medium, and large-scale forged items, the company manufactures heat treatment products according to customer needs by securing technological power for local heat treatment. Korea Industry is also strengthening its global competitiveness by responding actively to the rapid environmental change, such as in line with the transition to Industry 4.0.

Information

- Address

- 23-9, Gongdan 1-ro, Sanam-myeon, Sacheon-si, Gyeong- sangnam-do, Korea

- Tel

- +82-55-852-5870

- Fax

Products

Heat treatment of automobile parts, construction machinery parts, agricultural parts, etc.

Certifications

IATF 16949, SQ, KOMATSU (Japan), SUMITOMO (Japane), KOBELCO (Japan), Clean Workplace, Materials, Parts, and Equipment Specialist

Production Facilities

Continuous-type furnace (QT, ISO, NOR), nitriding furnace, shot peening machine, etc.

Ppuri Technologies

Intensive quenching technology

History

-

1986 Korea Industry established (Jinju, Gyeongsangnam-do)

2005 Won Production Infrastructure Technology Contest, entered into industry – academia agreement (Jinju National Industrial University)

2006 Won designation as Excellent Company in Quality Innovation, extended and relocated plant (Sacheon, Gyeongsangnam-do)

2009 Won Venture Business certification

2019 Won appreciation plaque from supplier (Shinil)

2021 Won Materials, Parts, and Equipment Specialist, Ppuri Technology Specialized Company, and Excellent Compa- ny in Risk Assessment certifications

Business Details and Production Items

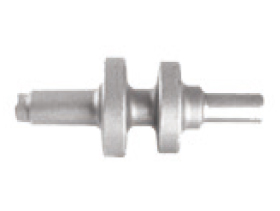

· Automobile: Crank shaft, outer ring, diff drive gear, hub clutch

· Construction Machinery: Roller, track link, head loader, end rear

· Agricultural Machinery: Bevel gear, final gear, wheel shaft, sprocket, spider

Features

Secured facilities and technological power for not only heat treatment of small, medium, and large-scale forged items, but also local heat treatment Obtained utility model for track bolt head heat treatment system

- Information

- Key Products

- Facilities

Key Products

Automobile

Construction machinery

Agricultural machinery

- Information

- Key Products

- Facilities

Production Facilities

-

QT continuous-type (pusher-type) furnace

QT continuous-type (pusher-type) furnace

-

QT continuous-type furnace

QT continuous-type furnace

-

ISO continuous-type furnace

ISO continuous-type furnace

-

Nitrification facility

Nitrification facility

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR