HEAT TREATIMENT

열처리

HANJUNG METAL

- Information

- Key Products

- Facilities

Hanjung Metal, a company specializing in heat treatment for defense and other industrial machinery parts, was established in 2004. The company is growing through continuous facility investment and quality and technological innovation.

Having obtained INNOBIZ and Venture Business certifications, Hanjung Metal is providing service according to customer needs by performing various quality improvement activities. Under the vision to become a greater company offering general heat treatment service based on technological competitiveness, Hanjung Metal is taking on new challenges to achieve growth.

Information

- Address

- 38-9, Dongdaeian-gil, Chilwon-eup, Haman-gun, Gyeong- sangnam-do, Korea

- Tel

- +82-55-586-5846

- Fax

Products

General heat treatment of defense and industrial machinery parts

Certifications

IATF 16949, SQ, ISO 9001, INNOBIZ, Venture Business, KITECH Partner

Production Facilities

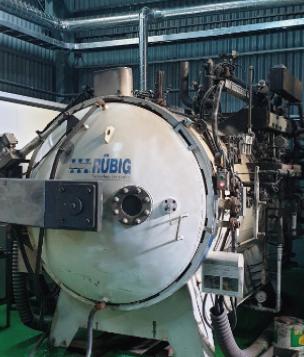

Press clinching (continuous-type furnace), pit-type nitriding furnace, salt bath nitriding furnace, vacuum furnace, pit furnace tempering machine, cleaning machine, shot machine, corrector

Ppuri Technologies

Atmospheric automatic control gas nitriding and carburization technology

History

-

Nov. 2004 Hanjung Metal established

Oct. 2006 Relocated to Haman-gun, Gyeongsangnam-do

Oct. 2007 Won Clean Workplace certification

Oct. 2008 Won ISO 9001

Nov. 2011 Won INNOBIZ and Venture Business certifications

Jun. 2015 Won IATF 16949 certification

2022 Won R&D Department certification and KITECH Partner certification

Business Details and Production Items

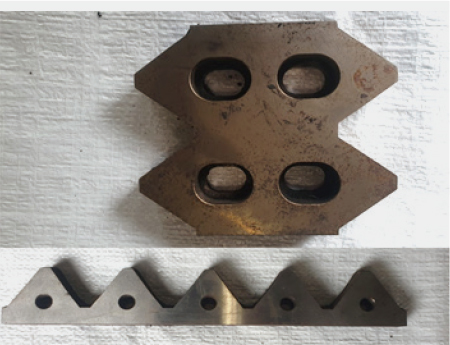

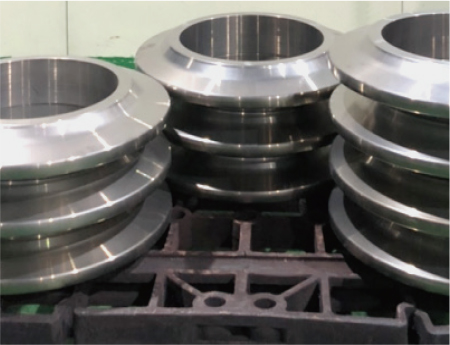

Heat treatment of large-scale bearing, projectile, bevel gear & pinion, K6 bolt, crushing knife, hot forging mold, crank shaft, cutter ring, curvic coupling, die, punch, hub, etc.

Features

Hanjung Metal has established a systematic quality system, and is performing quality management and improvement activities in order to provide products and services according to customer needs.

Hanjung Metal achieve customer satisfaction by eliminating defects, complying with delivery requirements, and conducting fol- low-up management based on strict quality control.

- Information

- Key Products

- Facilities

Key Products

-

Large bearing

Large bearing

-

Projectile

Projectile

-

Bevel Gear & Pinion

Bevel Gear & Pinion

-

K6 bolt

K6 bolt

-

Crushing blade

Crushing blade

-

Hot forging mold

Hot forging mold

-

Crank shaft

Crank shaft

-

Cutter ring

Cutter ring

-

Curvic coupling

Curvic coupling

-

Die

Die

-

Punch

Punch

-

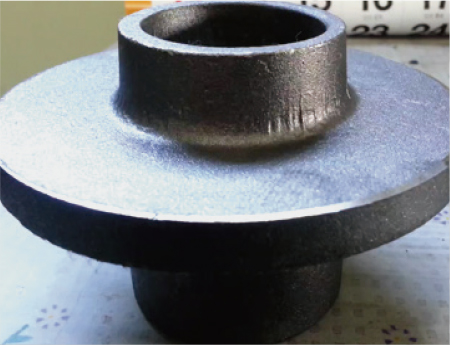

Hub

Hub

- Information

- Key Products

- Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR